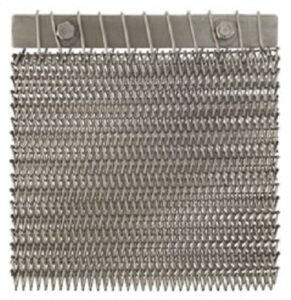

Boiler Armor™ flexible mesh drip screen is the solution you need to eliminate challenges in bottom ash handling. If you’re looking for a better way to manage bottom ash in your plant, our custom-manufactured product can get the job done!

Boiler Armor™ Flexible Mesh Drip Screen

Boiler Armor™ is designed to:

- Protect the seal skirt from radiant heat

- Keep particulate from entering the seal trough

- Allow clinker impact to be absorbed upon flex

- Reduce damage to the refractory wall

- Trap fine particles and sift them downward.

- Three dimensional design acts as a self-cleaning agent while the unit is online

In addition, Boiler Armor™ offers several advantages over the original equipment manufacturer’s product. It is easier to use than rigid wire cloth, solid stainless steel plate and castings. It can remain in place during routine maintenance – just roll it up out of the way to gain access.

How can you be sure that Boiler Armor™ is the right solution for your operation? American Energy Products has engineering staff that specializes in evaluating your unique situation. We have decades of experience dealing with common issues that can occur when using standard screens such as weak mounting options, corrosion, warpage and peeling. We offer solutions to the most challenging environmental issues: heat and corrosion. Boiler Armor™ is available in a wide range of alloys, in either single or double ply flexible mesh. Our experts will evaluate and recommend an alloy that will meet the unique needs of your application to ensure the most effective protection for the seal trough and seal skirt.

What makes Boiler Armor™ the right solution for your needs? It replaces hard to use wire cloth and plate, and offers ease of access to the seal trough. Installation is simple, saving time and money. Lacing wire is included with every order. This allows the installer to loosely lace the ends together, which prevents warpage and premature peeling. Our custom mounting assemblies ensure the right fit, and our custom-engineered alloys offer increased durability and extended life.

If this sounds like the solution you’ve been looking for, contact us at American Energy Products. We will inspect your operation, determine the best materials for your custom solution, and walk you through the entire process start to finish.

Posted in General