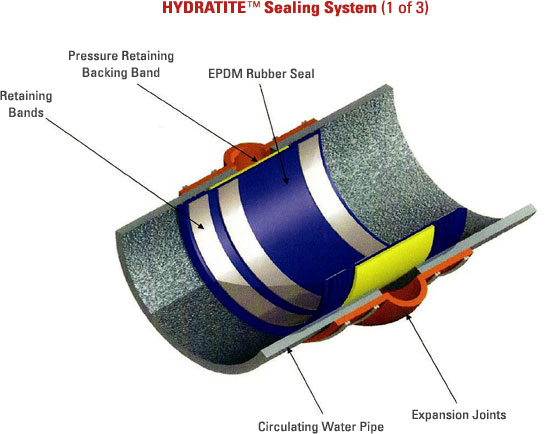

Hydratite is a mechanical remediation for pipe joint repairs. Hydratite is an EPDM rubber seal held in place with an individualized custom made seal that is held in place by stainless steel retaining bands. The seals can be interlocked to span long lengths of pipe, or a backing plate utilized to remediate expansion. The backing plate is held in place on one side of joint by a third retaining band. This allows for expansion, in conjunction with maintaining a tight seal. While the Hydratite repair cost is significantly less than other direct replacements, the duration of installation is reduced to days instead of standard alternatives consisting of weeks, it also provides a long term, economical, and efficient alternative without having to replace the existing joint seal. Hydratite is most typically applied on Bell & Spigot joints, Flanged joints, and expansion joints within the power generation pipelines, storm drain sewer systems, gas pipelines, potable water storage & distribution, etc.

What is HydraTite™?

HydraTite™ is an engineered, internal mechanical repair of pipe joints to eliminate infiltration and pipe joint leaking.

Where is HydraTite™ applied?

Joint repair, expansion joint remediation, end seal for CIPP, manhole chimney seal, seal off abandon laterals, and flexible pipe liner applied to power generation pipelines, storm drains, sewer systems, gas pipelines, potable water storage and distribution.

Do I need to remove my current existing expansion joint?

No. HydraTite™ is designed to replace existing expansion joints, without removing the original expansion joint. This saves labor time and money.

How long does HydraTite™ last?

HydraTite™ has a 50 year design life.

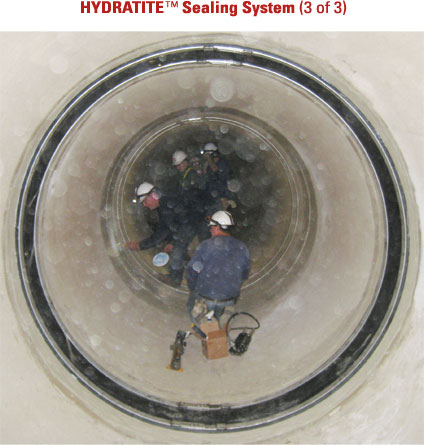

Who can install HydraTite™?

Our manufacturer certified contractors will come to you and install the HydraTite™ seal. This is part of the turn-key application and is essential in ensuring proper application.

What is the difference between HydraTite™ and other repair solutions?

HydraTite™ is a rapid installation and return to service and is ideal for immediate or emergency solutions, proven technology, trenchless remediation (no digging), no hot work required, seals can be interlocked to form a continuous repair over long lengths of pipe, low profile ensures minimal flow loss, ease of installation and cost savings compared to direct replacements and seal flexibility accommodates shifting, vibration and thermal expansion and contraction.